Sitong autoclave is large pressure vessel for steam curing, has excellent thermal insulating quality, and it is easy installed. Mostly, it is used for autoclaved aerated concrete plant (AAC plant) and wood preservation (or other wood processing). The autoclave is a horizontal cylinder device, when curing the aerated concrete, there is hydrothermal reaction (CaO-SiO2-H2O) happened in autoclave. Wood preservation autoclave could also be applied to different wood processing, such as fire retardant, mothproof, dyeing, coking, and degrease, etc. It has the advantages of wide applicability, good treat efficiency, large capacity, reasonable layout, and safety operation, etc. Based on customers’ requirement, the autoclave door could designed as manual and automatic operation.

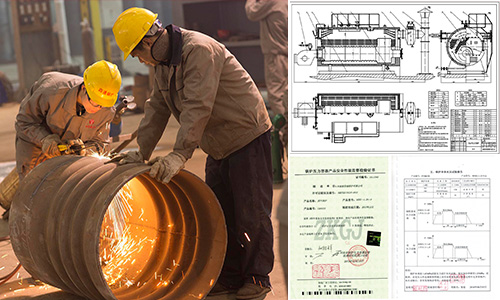

1) There is a professional design engineer team, before manufacturing, every boiler design drawing have to be approved by boiler and pressure vessel experts of CSBTS ( State Bureau of Quality Technical Supervision ), and then the boiler could be produced only if qualified.

1) There is a professional design engineer team, before manufacturing, every boiler design drawing have to be approved by boiler and pressure vessel experts of CSBTS ( State Bureau of Quality Technical Supervision ), and then the boiler could be produced only if qualified.

| Model | Internal diameter (m) | Effective length(m) | Max working temperature (°C) | Max working pressure(Mpa) | Designed pressure(Mpa) | Designed temperature(°C) | Working medium | Overall dimension L×W×H (mm) |

Weight (ton) |

| FGZCS1.0-1.65×21 | 1.65 | 21 | 184 | 1 | 1.1 | 187 | Saturation steam | 22650×2619×2695 | 21.5 |

| FGZCS1.3-2×21 | 2 | 21 | 194 | 1.3 | 1.4 | 198 | 23300×2980×3340 | 24.7 | |

| FGZCS1.3-2×27 | 2 | 27 | 194 | 1.3 | 1.4 | 198 | 2930×2980×3340 | 30.5 | |

| FGZCS1.3-2×31 | 2 | 31 | 194 | 1.3 | 1.4 | 198 | 33300×2980×3340 | 33.4 | |

| FGZCS1.3-2.5×27 | 2.5 | 27 | 194 | 1.3 | 1.4 | 198 | 29560×3254×4117 | / | |

| FGZCS1.3-2×31 | 2.5 | 31 | 194 | 1.3 | 1.4 | 198 | 33560×3254×4117 | / | |

| Notes: 1. Parameter is for reference only, if any changes should follow actual drawings. 2. Sitong boiler could design the specific industrial autoclave based on customers’ requirement. |

|||||||||

Contact us now if you have any question about our company and products [email protected]. Any of your inquiry and suggestion will be highly appreciated. We will keep your information completely private.

WANT TO FIND A BOILER FOR YOUR COMPANY ?CONTACT US