Introduction:

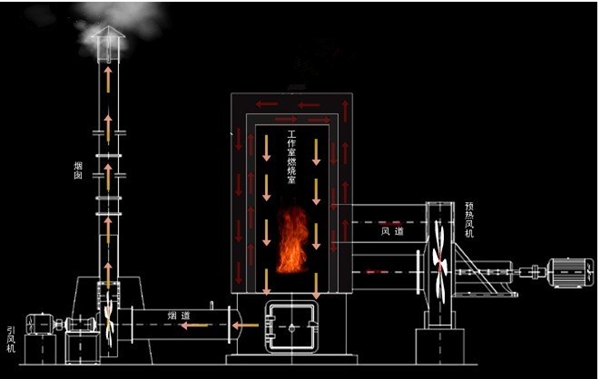

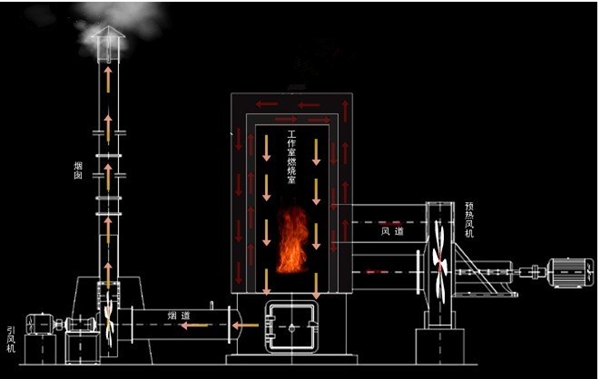

The hot air furnace combustion chamber and heat exchanger in one combined, using the structure of full steel plate multi-layer sleeve type, it's consumption chamber in the below of furnace center, circles heat exchanger in the upper and around, air and flue gas are two-pass, flow separately in heat exchanging. In order to improve thermal efficiency, the multiple head helical groove plate heat exchanging technology and turbulent flow principle, thinning laminar flow thickness, make the air and flue gas constantly exchange revolving on the march, greatly strengthened the heat transfer effect.

Working Process:

It produces high temperature flue gas in the furnace by burning of coal, going into smoke ring under the action of fan, and after the heat exchanging with the outside air, through the flue gas ducting and then discharged by chimney, the cold air blows into the shell of the stove by blower, getting into furnace lateral air ring through furnace arch the stove chamber into the lateral air ring, and supply clean hot air equipment by hot air outlet piping.

Performance Characteristics:

1. The fuel is coal/wood pellet/biomass

2. The hot air furnace use the pure hot air as the medium, no pollution.

3. Low power consumption, high thermal efficiency.

4. Auto measuring temperature and displaying.

5. Simple operation, easy to use. The equipment is all from domestic, its performance guideline reach to national advanced level.

Parameter

| Name |

Thermal Efficiency(%) |

Hot Air Outlet Temperature(C) |

Heating Supplied(mw) |

Air Volume(Nm³/h) |

Fuel available |

Diameter(mm) |

Height(mm) |

| ZLRF-10 |

70 |

200-300 |

0.12 |

3297-2198 |

Coal/wood pellet/biomass |

1220 |

2450 |

| ZLRF-20 |

70 |

200-300 |

0.24 |

3847-3572 |

1500 |

2740 |

| ZLRF-30 |

70 |

200-300 |

0.35 |

5447-3912 |

1750 |

3500 |

| ZLRF-40 |

70 |

200-300 |

0.47 |

6445-7513 |

1840 |

3790 |

| ZLRF-60 |

75 |

200-300 |

0.7 |

6786-7532 |

1850 |

4350 |

| ZLRF-80 |

75 |

200-300 |

0.93 |

7813-8685 |

2100 |

6395 |

| ZLRF-100 |

75 |

200-300 |

1.17 |

8867-9984 |

2340 |

6400 |

| ZLRF-120 |

75 |

200-300 |

1.4 |

10556-12370 |

2500 |

6800 |

Note: The parameters are for reference only. Any changes, the actual drawings shall prevail.

Transaction Process

Customer Inquiry -- Offer Professional Consulting Service -- Place Order -- Customize Boiler Based on Customers’ needs --Production-manufacturing -- Payment -- Impeccable After Sale Service (installation and debugging, periodic maintenance, etc.)

Offered Technical Documentations

Installment and Operation Instruction

Quality Certificate

Inspection Certificate of Boiler quality

General Drawing of Boiler

Foundation Drawing

Boiler Body Drawing

Boiler Room Design Drawing

Drawing of Valves, Instruments and Accessories

Company Strength

Sitong boiler is a national approved and designated enterprise, with design and manufacture license permits of Class A boiler and D1, D2 pressure vessel. The company has passed ISO 9001 international quality system certification, and gained the international certificates of CE, SGS, and BV, etc. The boiler products are exported to more than 60 countries. The factory covers an area of 120 thousands㎡, equipped with plenty of international advanced manufacture equipment, such as CNC cutting machine, automatic submerged arc welding machine, X-ray detection machine, etc.