![[alt2]](/v1/d/pic/product/szl-3.jpg)

We're here to help:Easy ways to get the answers you need

Parameter

| Model | Rated evaporation capacity(t/h) |

Working pressure (MPa) |

Rated steam temperature/ outlet temperature(℃) |

Fuel type | Overall dimension part for transportation L*W*H(mm) |

|

| SZL2-0.8/1.0/1.25/1.6/2.5-T | 2 | 0.8/1.0/1.25/1.6/2.5 | 175/184/194/204/226 | II-class soft coal, Low calorific value Q≈21000KJ/Kg |

5500×2350×3650 | |

| SZL4-1.0/1.25/1.6/2.5-T | 4 | 1.0/1.25/1.6/2.5 | 184/194/204/226 | 7730×2360×3520 | ||

| SZL6-1.0/1.25/1.6/2.6-T | 6 | 1.0/1.25/1.6/2.5 | 184/194/204/226 | up 6150×2840×3540 | down 7275×2852×2580 | |

| SZL8-1.0/1.25/1.6/2.7-T | 8 | 1.0/1.25/1.6/2.5 | 184/194/204/226 | up 6971×2933×3540 | down 8056×2945×2580 | |

| SZL10-1.0/1.25/1.6/2.8-T | 10 | 1.0/1.25/1.6/2.5 | 184/194/204/226 | up 7855×3240×3540 | down 9025×3200×2580 | |

| SZL15-1.0/1.25/1.6/2.9-T | 15 | 1.0/1.25/1.6/2.5 | 184/194/204/226 | up10000×3240×3540 | down 12000×3200×3080 | |

| SZL20-1.0/1.25/1.6/2.10-T | 20 | 1.0/1.25/1.6/2.5 | 184/194/204/226 | up 11000×3240×3540 | down 14000×3200×3080 | |

Offered Technical Documentations

Installment and Operation Instruction

Quality Certificate

Inspection Certificate of Boiler quality

General Drawing of Boiler

Foundation Drawing

Boiler Body Drawing

Boiler Room Design Drawing

Drawing of Valves, Instruments and Accessories

Company Strength

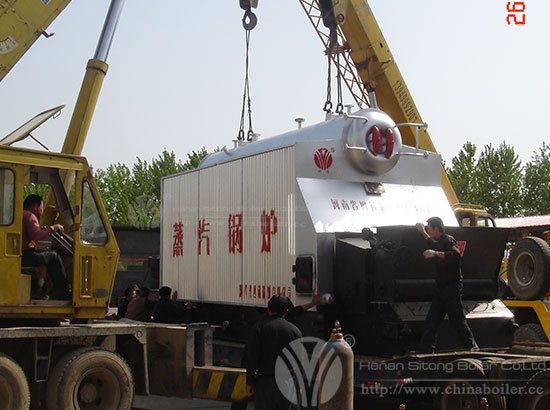

Sitong boiler is a national approved and designated enterprise, with design and manufacture license permits of Class A boiler and D1, D2 pressure vessel. The company has passed ISO 9001 international quality system certification, and gained the international certificates of CE, SGS, and BV, etc. The boiler products are exported to more than 60 countries. The factory covers an area of 120 thousands㎡, equipped with plenty of international advanced manufacture equipment, such as CNC cutting machine, automatic submerged arc welding machine, X-ray detection machine, etc.

Contact us now if you have any question about our company and products[email protected]. Any of your inquiry and suggestion will be highly appreciated. We will keep your information completely private.

| Name* | Tel* | ||

| E-mail* | |||

| Message* | |||